- Toll Free 1.855.4RICE.RT

- Contact Us

-

Sign In

Duoline® 20

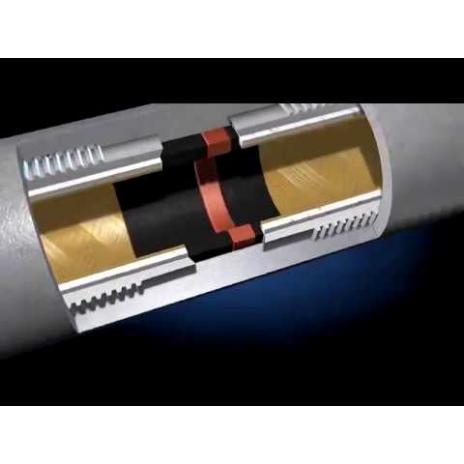

Duoline 20 is the workhorse of the Rice liner systems offering a broader range of application coverage in terms of more demanding downhole chemistry, durability and temperature requirements. Initially developed by Rice Engineering in 1971, it employs a durable filament wound glass reinforced epoxy (GRE) liner sleeve refined over the previous 45+ years. Duoline 20 offers a proven track record in a range of demanding environments with temperatures up to 121˚C (250˚F) and various chemical compositions including high concentrations CO2, H2S and chlorides.

-

Duoline 20 lowers life cycle costs by offering a more durable, longer lasting corrosion protection than traditional IPC coatings. With over 100 million feet installed worldwide, Duoline 20 has documented in-service installations lasting over 3 times longer than competitive coatings and lining systems.

Features & Benefits:

- A proven performance with over 100 million feet installed worldwide, documenting exceptionally long life in-service installations exceeding 35 years.

- Easy and fast installation that does not require specialized pipe, can be applied to new or used tubing, and can be used with most standard or premium connection types.

- Durable corrosion protection with physical abrasion and impact resistance in wireline and coiled tubing service.

- A high-hoop strength modulus liner which does not rely on an adhesive or chemical bond to tubing, making the system non-susceptible to collapse or debonding during de-pressurization.

- A broad range of chemical resistance offering application flexibility and a wider range of service.

- Installation into customer-preferred tubing and connection systems, no requirement for high-cost CRA alloys or premium connections.

- A cost-effective solution with lower operating costs and longer lifecycles than other coatings or lining systems.

Primary Applications include:

- Water & Sour Gas Injection Wells

- Disposal Wells

- Industrial Wastewater Disposal

- ESP Water Source Wells

- Sour Gas Production Wells

- Carbon Capture Storage Wells

- Gas-Lifted Production Wells

Product Characteristics:

- Nominal Working Temperature: 121oC (250oF)

- General Chemical Resistance: HCI Acid = YES, HF Acid = NO, Strong Caustics = NO, Hydrocarbons, Produced Oil & Water = YES

- Working temperature ratings should be adjusted by Rice for significant levels of CO2, H2S, solvents, caustics or acids.

- Absolute Roughness: 5 micron or 0.00021 inches, or use C = 150 for Hazen Williams friction loss formula.

Guidelines:

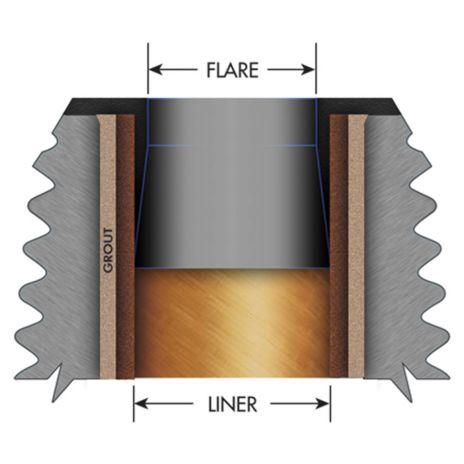

- Drift Diameter General Rule: Maximum tool diameter should be 6.35 mm (0.25 inch) smaller than flare diameter.

- Recommended Wireline Speed: 30 m/min (100 ft/min) in and out, and tools/wireline/cables shall be free from sharp corners or burns.

- Do not allow tools or bars to “free-fall” through DUOLINE and do not perforate through DUOLINE or liner damage will be expected.

- Recommended Pressure Release Rates: In Gas Service: 100 psi/min (700 kpa/min) In Water Service: Use a 5 - 10 second release.

- Ratings for Working Pressure/Tension/Compression/Bending: Up to rated steel pipe body limits. Do not exceed elastic limits.

- While operating, following the recommendations contained within Rice’s BEST PRACTICE GUIDELINES FOR DUOLINE TUBULAR GOODS will significantly extend they useful life of your tubing investment. To obtain a copy, please contact Rice.

+