- Toll Free 1.855.4RICE.RT

- Contact Us

-

Sign In

Duoline® 10

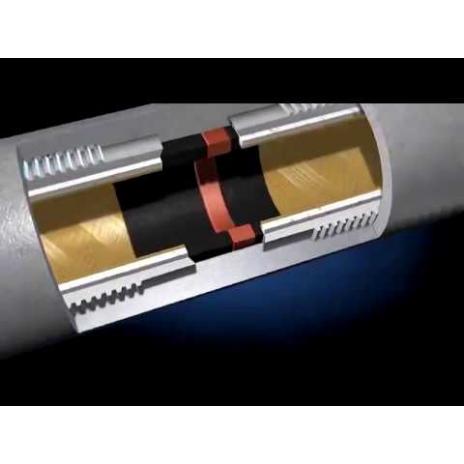

Providing unmatched performance in eliminating pipe corrosion, Duoline 10 is the original lining system developed by Rice Engineering in 1965. It employs an extruded polyvinyl chloride liner sleeve and can be used in applications with temperatures up to 65°C (150°F). Numerous installations have exceeded over 40 years continuous corrosion-free service.

-

Duoline 10 lowers life cycle costs by offering a more durable, longer lasting corrosion protection than traditional IPC coatings. It extends tubing life in difficult conditions by being abrasion resistant to wireline and coiled tubing procedures. Additionally, the lining system does not require specialized pipe, and can be applied to new or used tubing with standard connections in just days.

Other benefits include:

- A proven performance with over 100 million feet installed worldwide.

- Exceptionally long life as documented in-service installations have lasted over 45 years.

- Durable corrosion protection with physical abrasion resistance in wireline and coiled tubing service.

- A cost-effective solution with similar up-front costs and lower operating costs to other coatings or lining systems.

Primary Applications include:

- Water Injection Wells

- Water Disposal Wells

- Industrial Wastewater Disposal

- ESP Water Source Wells

- Wells with low concentrations of CO2 & H2S (<1%)

Product Characteristics:

- Nominal Working Temperature: 65oC (150o F)

- General Chemical Resistance: HCI Acid = YES, Solvents such as Toluene & Xylene = NO, Gas Injection = NO

- Working temperature ratings should be adjusted by Rice for significant levels of CO2, H2S, solvents, caustics or acids.

- Absolute Roughness: 5 micron or 0.00021 inches, or use C = 150 for Hazen Williams friction loss formula.

Guidelines:

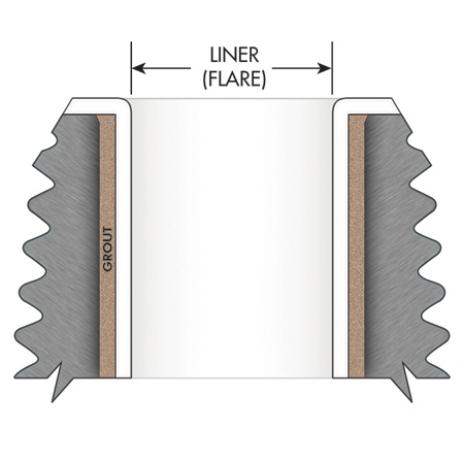

- Drift Diameter General Rule: Maximum tool diameter should be 6.35 mm (0.25 inch) smaller than flare diameter.

- Recommended Wireline Speed: 30 m/min (100 ft/min) in and out, and tools/wireline/cables shall be free from sharp corners or burns.

- Do not allow tools or bars to “free-fall” through DUOLINE and do not perforate through DUOLINE or liner damage will be expected.

- Recommended Pressure Release Rates: In Water Service: Use a 5 to 10 second release of pressure, do not drop pressure instantly.

- Ratings for Working Pressure/Tension/Compression/Bending: Up to rated steel pipe body limits. Do not exceed elastic limits.

- While operating, following the recommendations contained within Rice’s BEST PRACTICE GUIDELINES FOR DUOLINE TUBULAR GOODS will significantly extend they useful life of your tubing investment. To obtain a copy, please contact Rice.

+